The Garbage Man Can

Baltimore has a bit of a floating debris problem. This outflow channel comes down from the city into the harbor and when the tide is…

Baltimore has a bit of a floating debris problem. This outflow channel comes down from the city into the harbor and when the tide is…

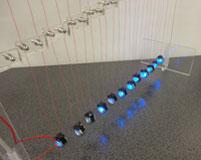

Do you know what a pendulum wave is? A few months ago, I didn’t either. But one day someone showed me a video of it…

The term simple machines should really be “simplest machines.” A can opener should count as a simple machine, but if pulleys, wheels, and levers are…

Printers are amazing machines. Even the simplest printers today have hundreds of parts and are capable of stunning print position accuracy. So much design, engineering…

With a simple flip and twist, this simple bookshelf: Became a very effective and IKEA-like iPad holder. With multiple display angles and a solid support…

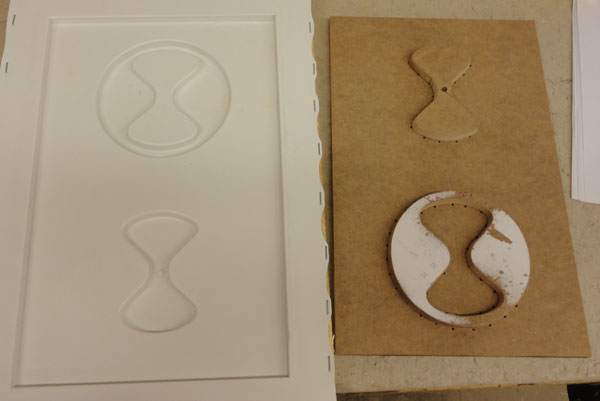

Combining my prototyping work with my tinkering, today I am going to share the process and the product of my latest project. This is the…